Compensators

REIFLEXA Compensator – Technic

REIFLEXA-Compensators are made from various elastomers and provide the flexible element in pipework that is indispensabel in todays technically advanced plant and machinery installations. By using well quality proven rubber compositions, combined with many years experience REIFLEXA-Compensators guarantee maximum safety and a high quality standard.

REIFLEXA-Rubber-Compensators provide:

- Compensation of thermal or mechanical pipework in axial, lateral or angular directions.

- Absorption/Isolation of vibration together with compensation for flexible mounting misalignment.

- The damping of pipework borne sound transmission.

- Combined sealing by flexible joint faces on the fittings.

- Special HIGH-PRESSURE types with shock and seaway movement capabilities are also available.

REIFLEXA-Rubber-Compensators are now able to replace expensive expansion bends within a smaller space.

QUALITY-CONTROL: Strict regular monitoring in modern laboratories by pressure and burst test experiments, ensure the required values are continually met.

Rubber – Compensators

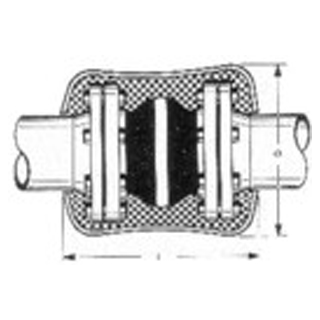

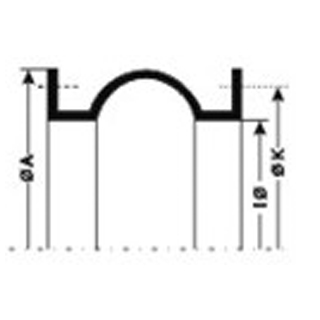

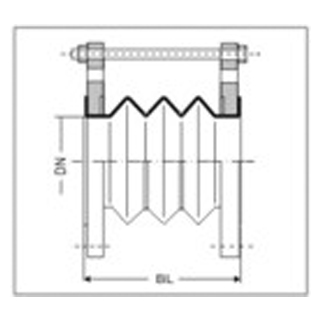

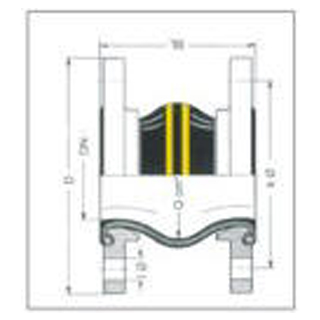

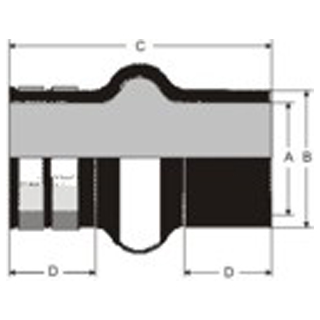

Rubber-Compensator Type 1A

Bl 130 / 200 / 250 / 300 mm

Rubber-Compensator Type 1A

Sheet 2

Rubber-Compensator Type GS – Steelwire

Bl 130 / 200 mm

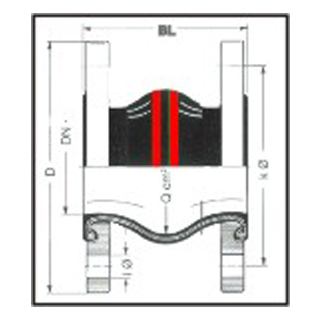

Rubber-Compensator Type HP – Hotwater

Bl 130 / 200 / 250 / 300 mm

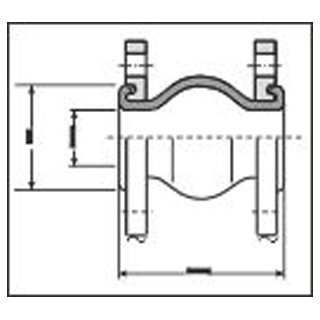

Rubber-Compensator Type 1B

Bl 150 mm

Rubber-Compensator Type 1C

Bl 100 mm

Rubber-Compensator Type 1S

Bl 160 mm

Rubber-Compensator Type1S

Sheet 2

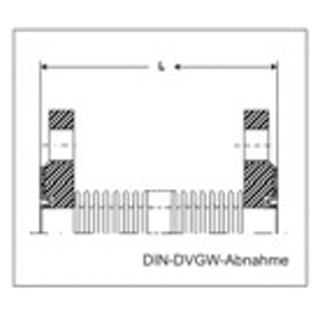

Rubber-Compensator Type 2

with Rubber flanges

Rubber-Compensator Type 2

Sheet 2

Rubber-Compensator Type TU

Rubber-Compensator Type 3K

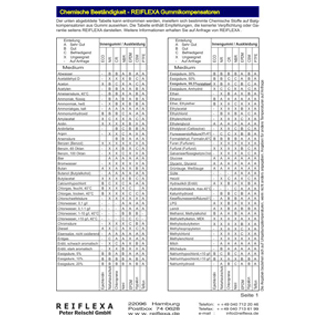

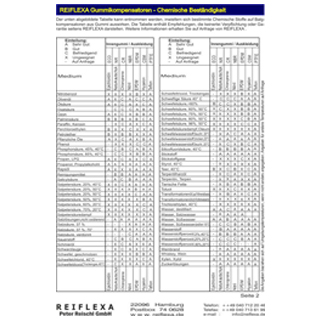

Qualities

If in doubt ask for the REIFLEXA- durability details.

For installation in corrosive surroundings, rubber compensators of all types can be supplied with a Teflon linings.

| Identification Marking | Inner Linning (Rubber) | Outside Cover (Rubber) |

|---|---|---|

| yellow | ECO or NBR, black For fresh-, cold-, seawater, as well as all known fuels and Petrol-Benzol-mixtures 50 : 50. | ECO or CR especially resistant for outside weather conditions, as well as oil,age, ozone and flame resistant |

| GS | NBR - Nitrile black For fresh-, cold-, seawater, as well as all known fuels and Petrol-Benzol-mixtures 50 : 50 and flame resistance without protection cover | Chloroprene (CR) See above |

| HO | NBR - Nitrile black For fresh-, cold-, seawater, as well as all known fuels and Petrol-Benzol-mixtures 50 : 50. Oiltemp. 110°C | Chloroprene (CR) see above |

| red | EPDM for heatings-systems with safe usage temperatures of 90° C. | EPDM ageing and water resistant |

| HP | EPDM for heatings-systems with safe usage temperatures of 130° C | EPDM see above |

| green | Hypalon (CSM) acid resistant rubber which can be used for most acids, however, quote the substance and the operating temperature. | Chloroprene (CR) see above |

| white | NBR - Nitrile white for drinking water, food and alcoholic beverages also with fat containing food r.h. oil. | Chloroprene (CR) see above |

Accessories for Rubber-Compensators

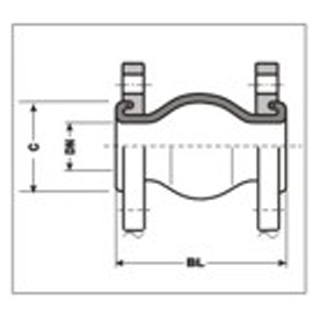

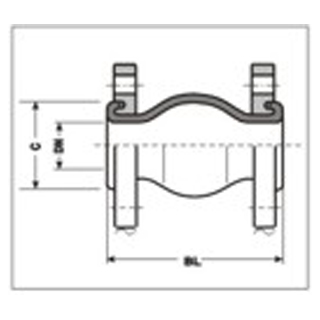

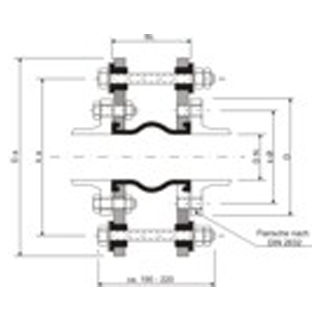

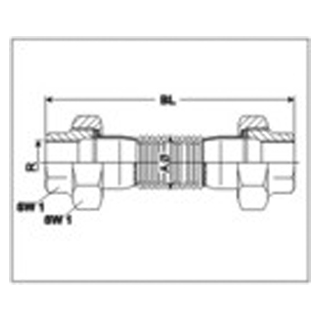

Tie rods for Type 1

DN 25 – 300

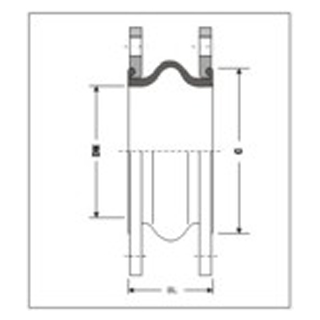

Tie rods for Type 1

DN 300 – 1000

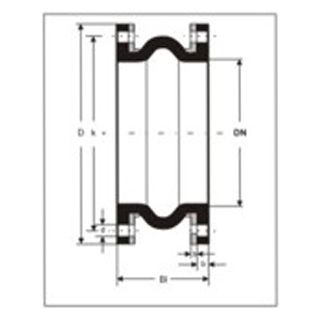

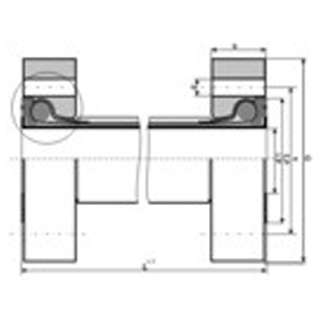

Tie rods for Type 2

Tie rods for Type 2

Steel-Compensators

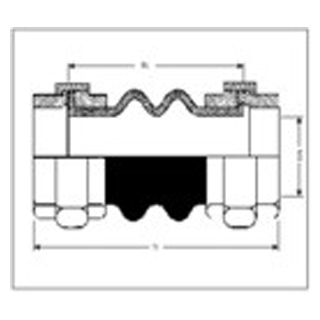

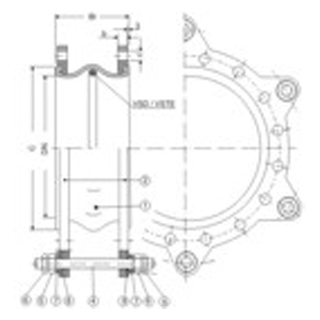

Steel-Compensator Typ FBK

Steel-Compensator Typ ST-K

Steel-Compensator Typ ST-HV

High-Pressure Compensators

High-Pressure Compensator

Type 0260

High-Pressure Compensator

Type 0265

High-Pressure Compensator

Type 0100

Special Compensators

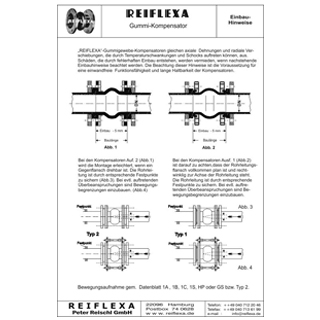

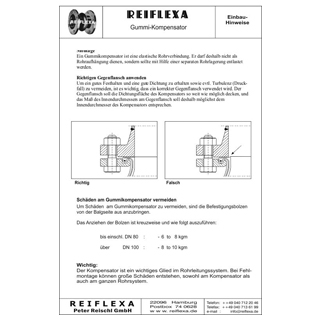

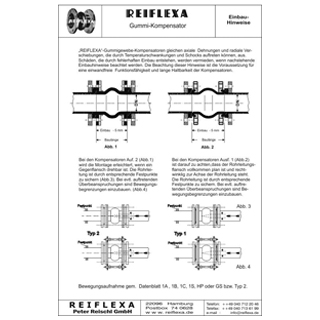

Install-Instruction

Installations-Instruction Sheet 1

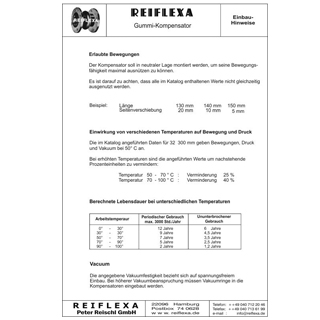

Installations-Instruction Sheet 2

Installations-Instruction Sheet 3